Secondary Battery Business

Total Solution Provider, PNT

PNT’s secondary battery business spans a wide spectrum, from customized turnkey solutions, mass production equipment, and lab & pilot systems to cutting-edge technologies such as dry processing and all-solid-state batteries. By building a complete full value chain from battery materials and process equipment to finished products PNT goes beyond simple equipment supply. We provide end-to-end manufacturing partnerships that encompass process design, technical consulting, and collaboration through our trusted network, positioning ourselves at the forefront of innovation in the secondary battery industry.

Technical Strengths

-

120m/minUltra-High-Speed Coater

for Electrode Production -

150m/minUltra-High-Speed Roll Press

for Electrode Production -

6.4ton/cmUltra-High-Pressure Roll Press

for Electrode Production -

1500mmUltra-Wide Substrate Width

for Electrodes -

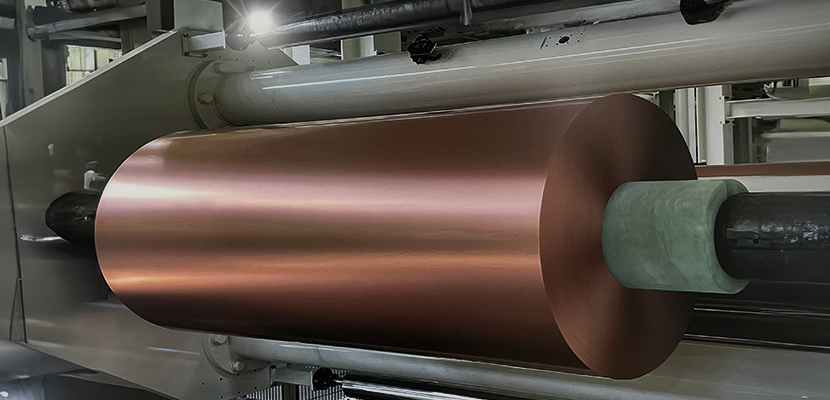

6umUltra-Thin Substrate Thickness

for Electrodes -

120m/minMaximum Production Speed

for Lithium-Ion Electrodes -

Copper / Al FoilOver 600 Units Delivered Worldwide

-

Battery Separate FilmThe Only Turnkey BSF Manufacturer in Korea

-

Active MaterialExclusive LFP Technology and Production Capability in Korea

-

Electrode CoatingA Global Leader in Electrode Coating & Calendering Solutions

-

AssemblyA Trusted and Experienced Engineering Partner

Turnkey

Turnkey equipment for secondary battery manufacturing is a high-barrier, high-complexity core competency that demands extensive project experience, deep technical expertise, and seamless communication with clients.Backed by over 20 years of know-how and proven track records, we design and integrate entire production processes not simply supplying machines, but building high-performance manufacturing infrastructure that helps our customers achieve their goals with precision and efficiency.

Founded in 2003, PNT is a specialized secondary battery equipment manufacturer with world-class technology across the entire process from electrode fabrication to cell assembly and formation. Our systems are designed to support high-volume manufacturing, seamlessly integrating inter-process connectivity, automation, and quality control tailored to the unique needs of various battery production environments. Through optimized engineering, we help customers establish scalable mass production systems that deliver real-world results and support global expansion.

Lab

From compact equipment tailored for specialized research labs to pilot lines optimized for sample production and early-stage validation, we offer a full range of small-scale systems ideal for R&D in secondary battery manufacturing. Our equipment is engineered to simulate real mass production conditions with precision and stability, enabling fast, repeatable testing of material properties and process parameters. Designed for flexibility and accuracy, our lab-scale solutions provide everything needed for rapid development, process validation, and customized innovation.

Process Flow

-

01

Mixing

Mixing -

02

Coating

Coating -

03

Calendering

Calendering -

04

Slitting

Slitting -

05

Notching

Notching

-

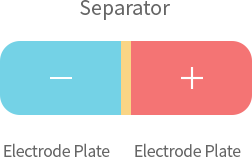

Electrode Process

-

The process of manufacturing positive (+) and negative (−) electrode plates

The process of manufacturing positive (+) and negative (−) electrode plates

-

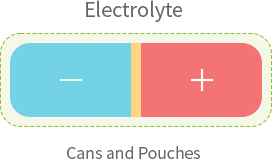

Assembly Process

-

The process in which electrodes and raw materials are processed and assembled into a finished product

The process in which electrodes and raw materials are processed and assembled into a finished product

-

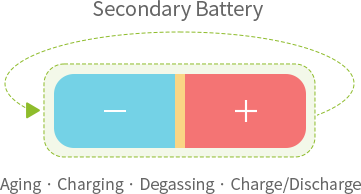

Formation Process

-

A process that assigns electrical properties through charging and discharging

A process that assigns electrical properties through charging and discharging

Industry Application

-

Secondary Battery Electrodes

Secondary Battery Electrodes -

Electrolytic Copper Foil

Electrolytic Copper Foil