Secondary Battery Machinery

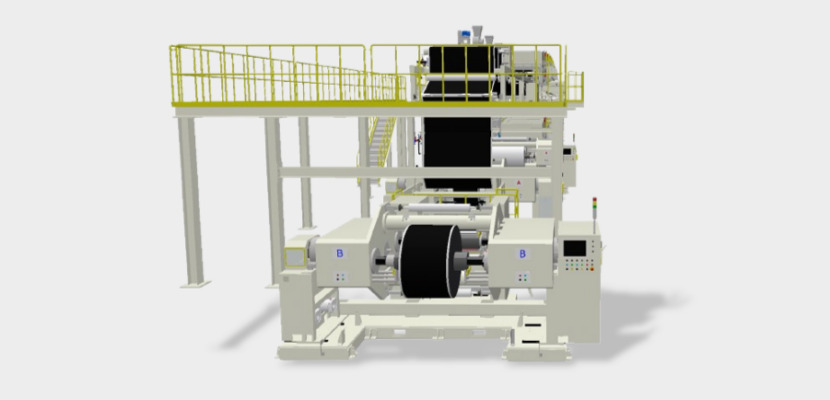

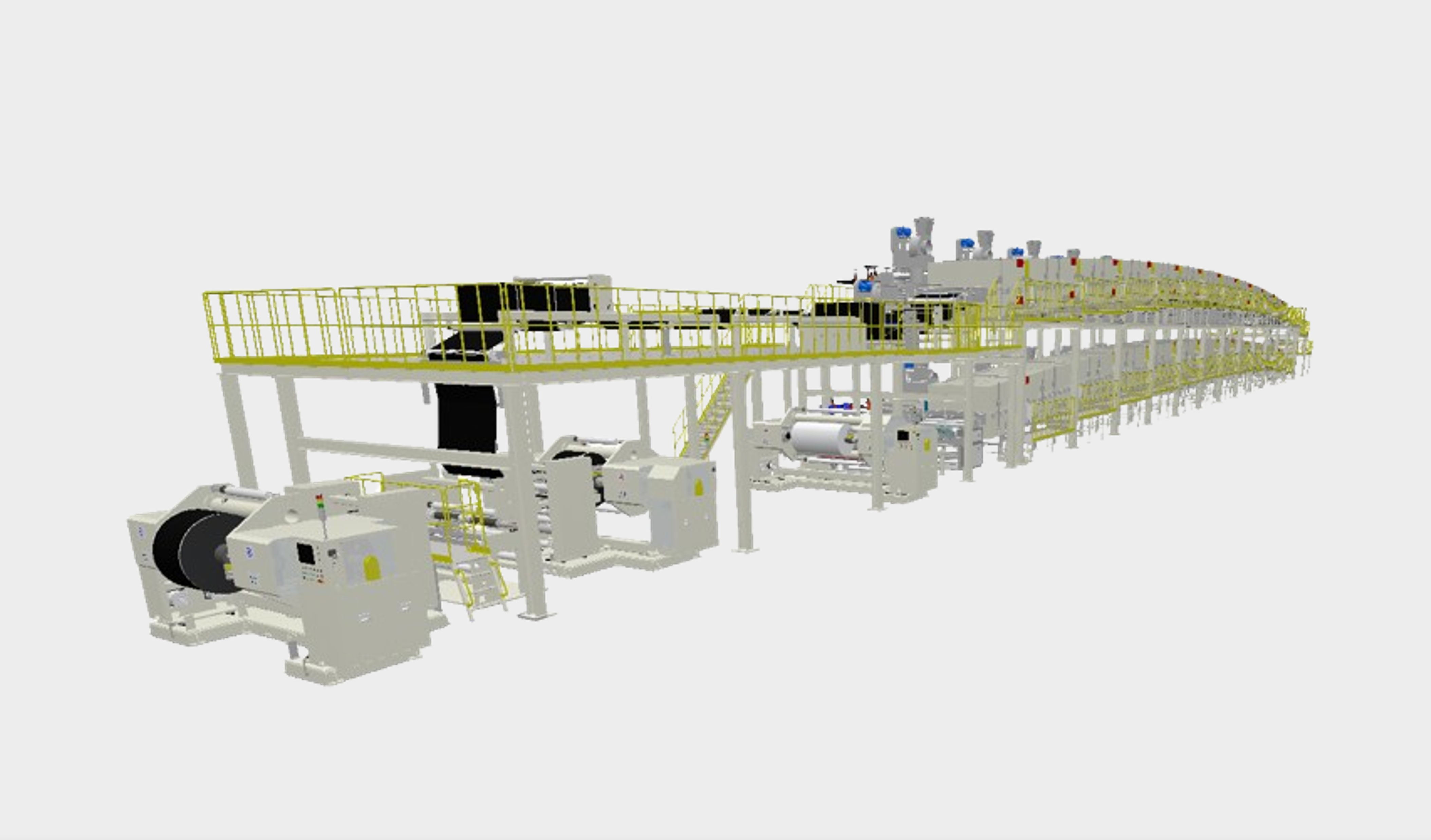

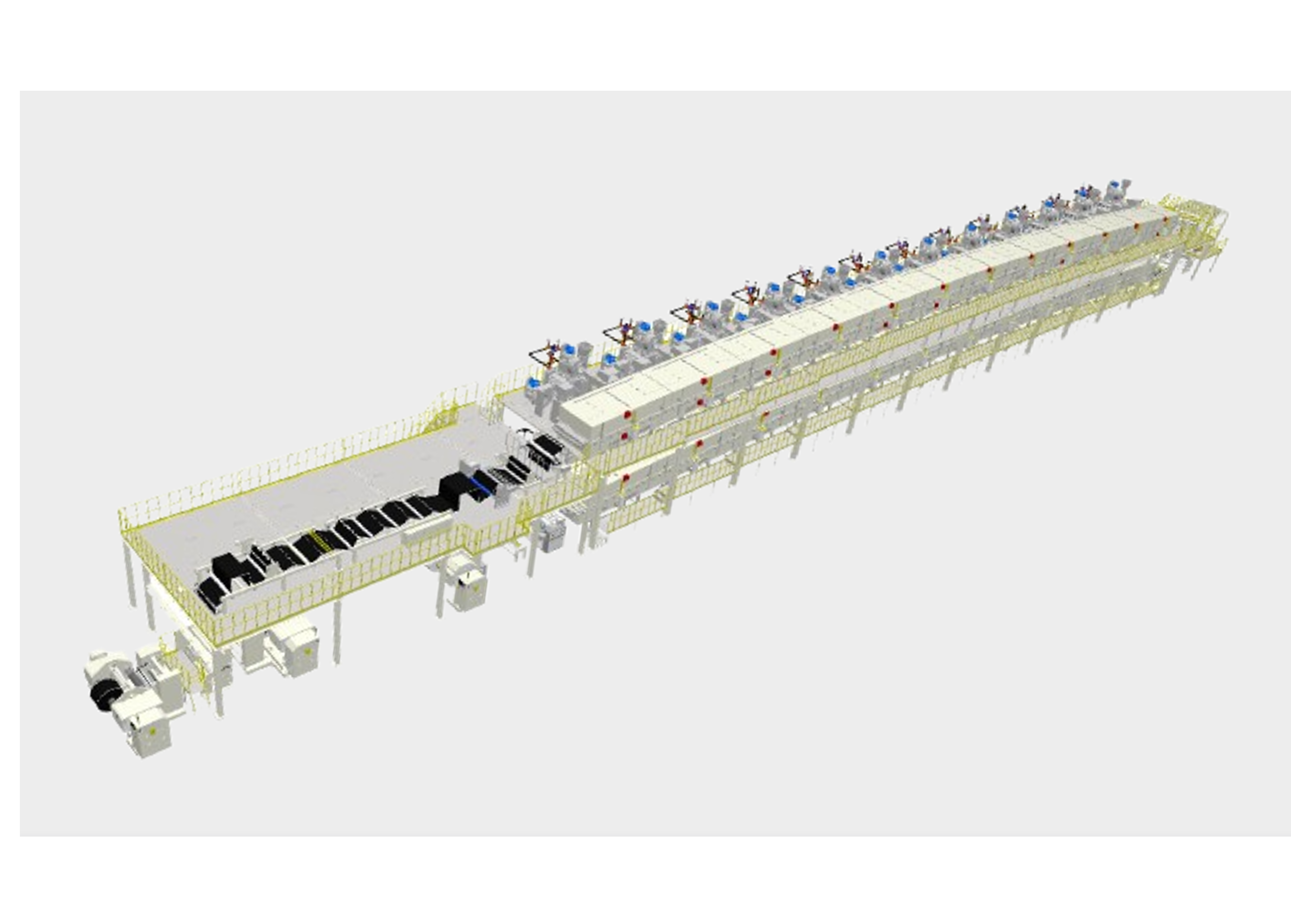

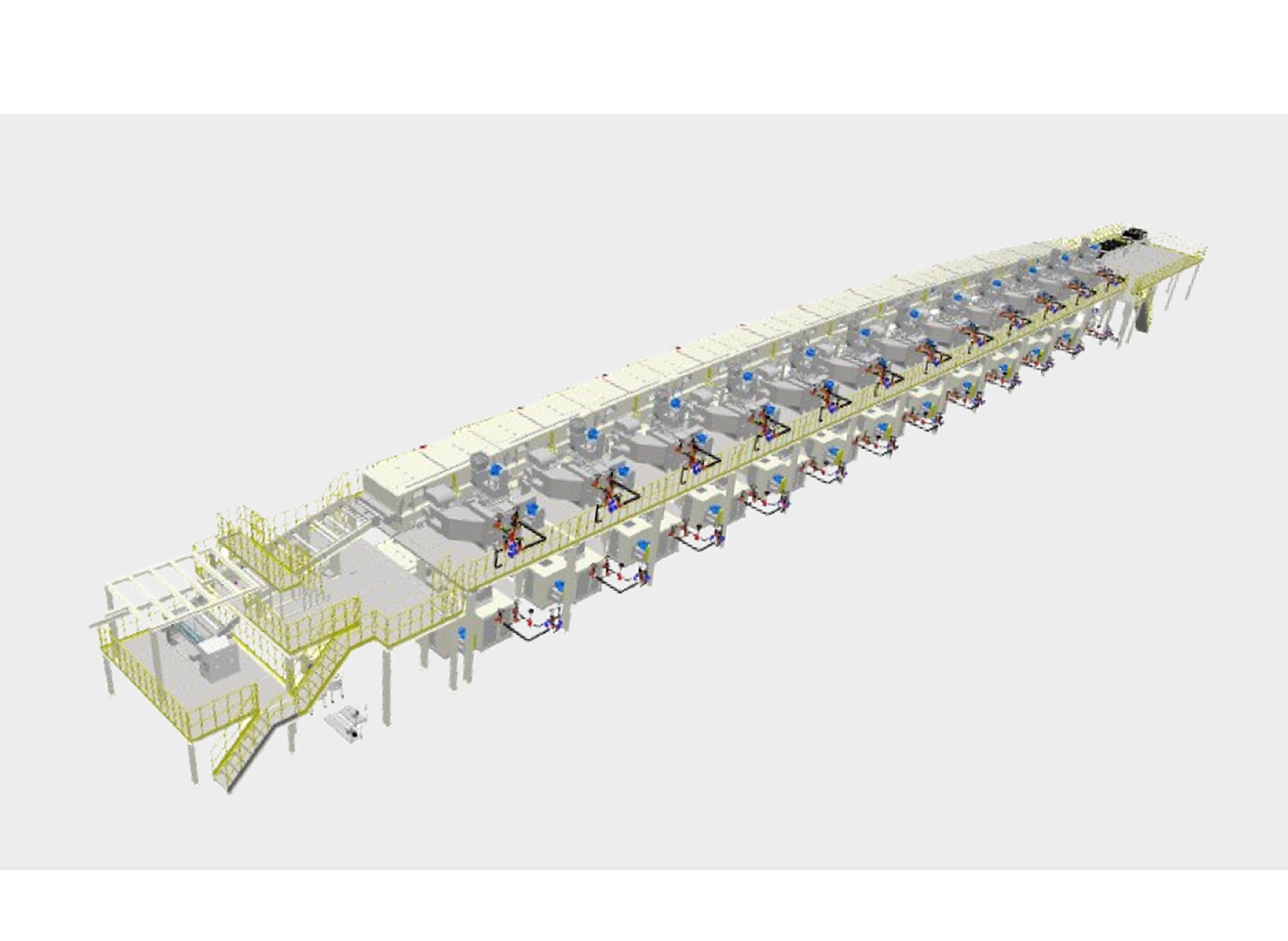

Electrode Coater

전극 코터

The electrode coater is designed for coating and drying active materials used in lithium-ion batteries.

Each layer is equipped with an 80-meter-long drying system, and double-sided coating enables a maximum production speed of up to 120 m/min. With drying systems installed on both the top and bottom, energy efficiency has been improved by over 30%, along with enhanced maintenance and operational convenience.

A key challenge in lithium-ion battery manufacturing is maximizing production efficiency by running wide-width substrates at high speeds. To meet these customer demands and rapidly evolving market trends, PNT integrates its own advanced technologies into the production process.

Specifications

| 구분 | 사양 |

|---|---|

| Production Speed |

Max. 100m/min

|

| Web Width |

Max. 1,400mm

|

| Web Thickness |

6μm ~ 15μm

|

| Coating Method |

Slot dieㆍSequential double-sided / 2-layer structure / Continuous and intermittent coating(Strip or Pattern)

|

| Coating Density |

0.3mg/cm²

|

| Drying Type |

Top ㆍ Bottom Opening Type

|

| Heating Source |

Electric heaterㆍSteam and Hot oil

|

| Inline Density Measurement |

Radiation-Based densitometer : Kr-85 β-ray(Measurement Points : Substrate, after A-drying, after B-drying)

|

| Required Space |

135m(L) * 11m(W) * 10m(H)

|