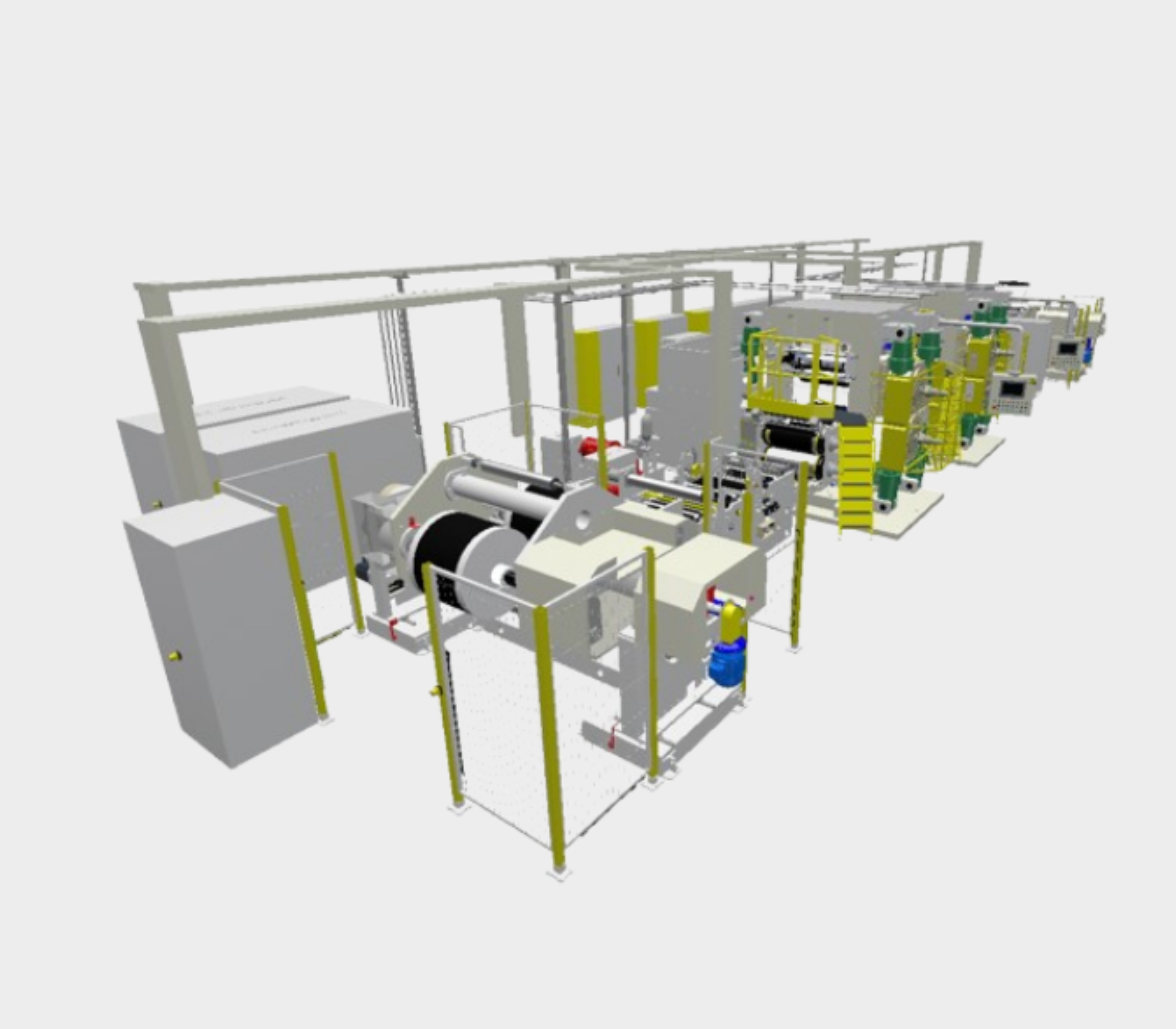

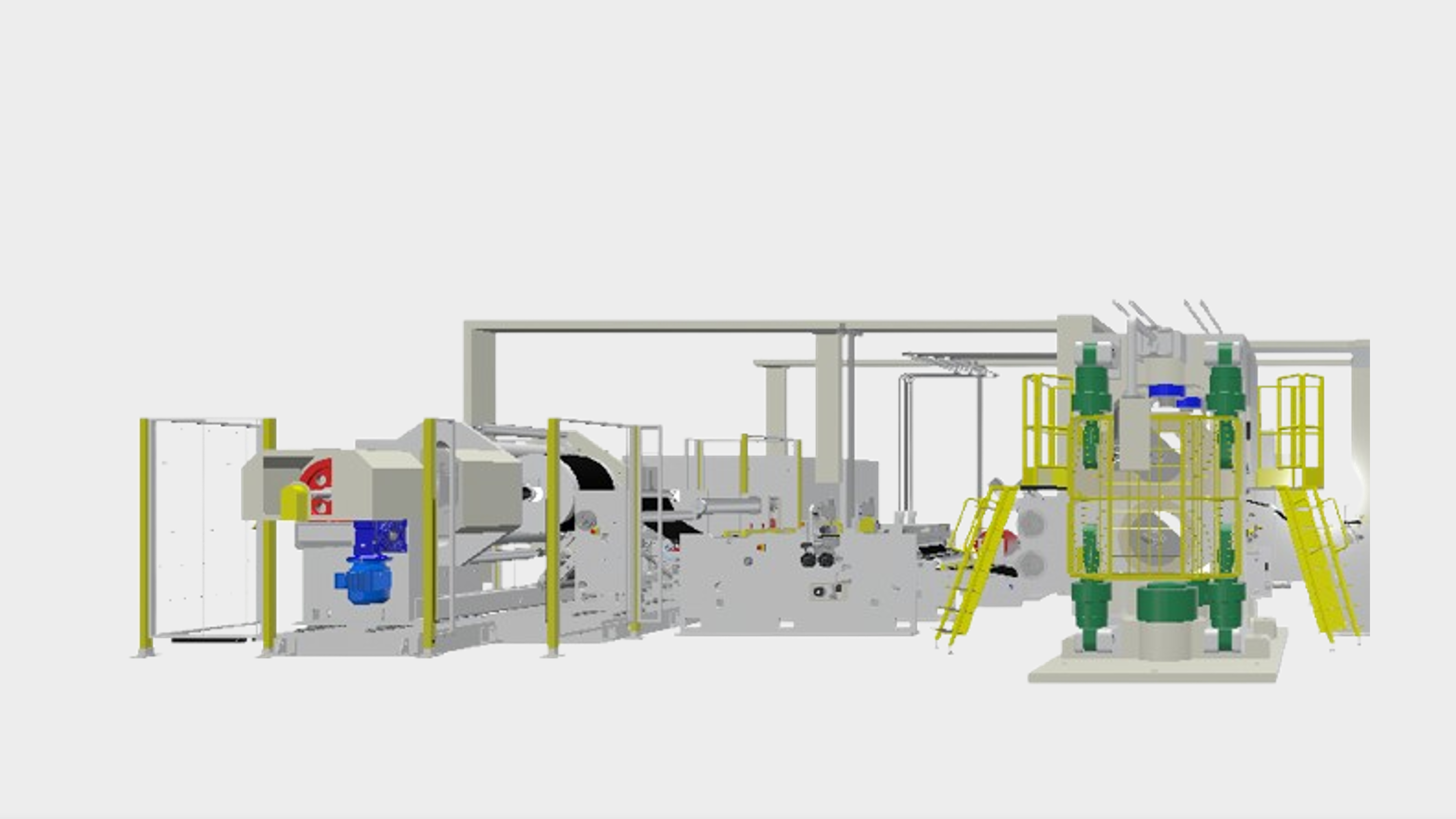

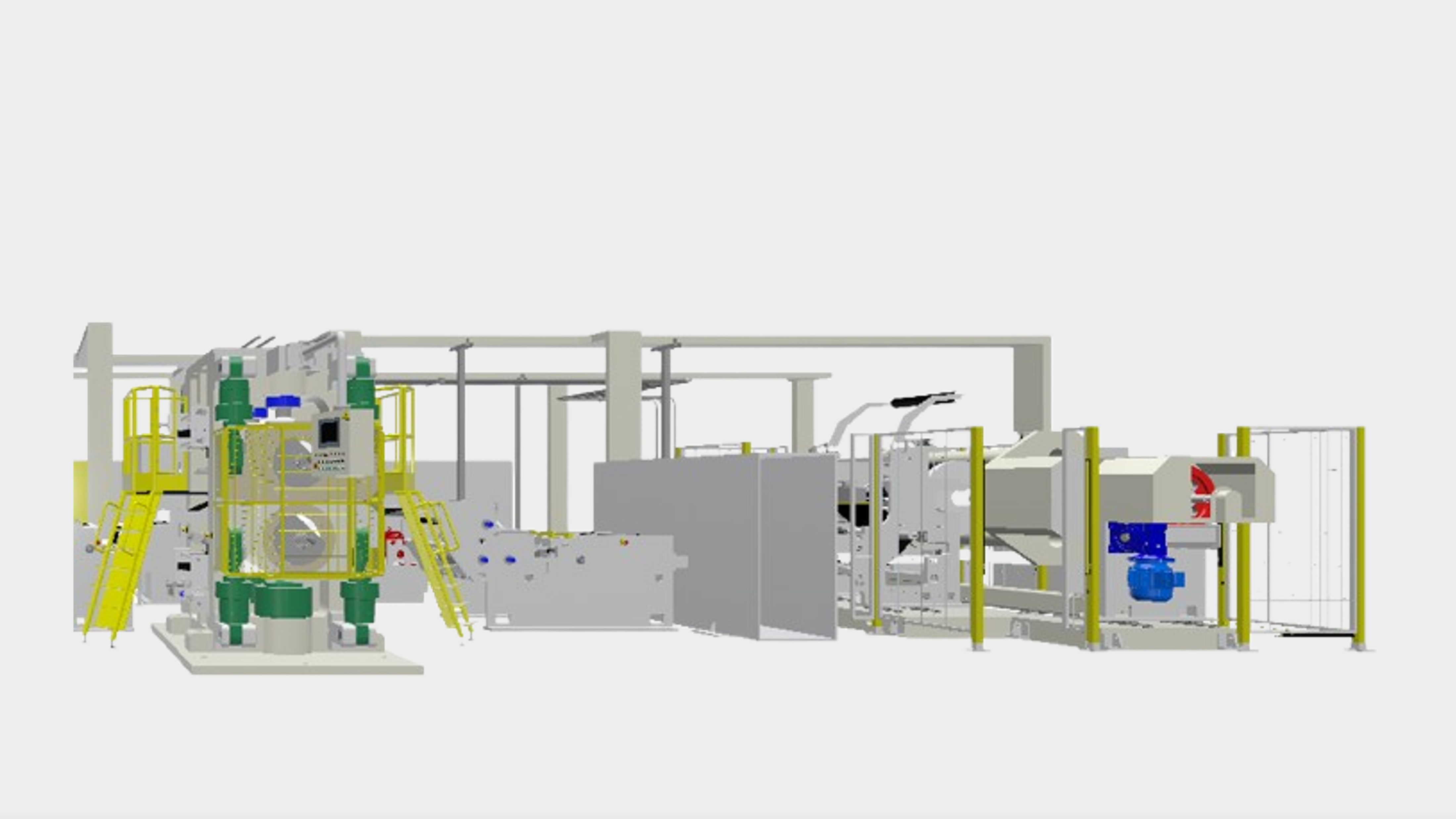

Electrode Calender(Roll Pressing Machine)

전극 롤프레스

The electrode calender is designed to roll the coated web while maintaining a consistent thickness.

The most critical factor in the rolling process is the precise control of the gap.

To apply uniform linear pressure across the entire electrode, pressure is exerted between the main rolls.

Using a hydraulic servo control system, reproducibility within 1μm is achievable. In the case of anode rolling, hot rolling is applied to achieve higher rolling speeds, while cathode rolling utilizes multi-stage rolling to prevent springback. Additionally, the system incorporates various advanced technologies, such as high-frequency induction heating, and features specialized functions, including a 1000N high-tensile stretching device.

Specifications

| 구분 | 사양 |

|---|---|

| Production Speed |

Max. 150m/min

|

| Web Width |

Max. 700mm

|

| Rolling Pressure |

Max. 6.4ton/cm

|

| Roll pressing method |

Cathode : Hot RollingㆍAnode : Cold Rolling / Upper Roll : FixedㆍLower Roll : Moves up and down / Hydraulic servo control system for the gap adjustment

|

| Thickness Control Deviation |

±1.5㎛

|

| Wrinkle Improvement Unit |

Wrinkle improvement unit / High tension web stretching unit

|

| Inline thickness measurement |

Beam shield shadow measurement systemㆍDistance measurement with a magnetic sensor

|

| Space |

15m(L) * 10m(W) * 4m(H)

|