ODF Coater

ODF 코팅 머신

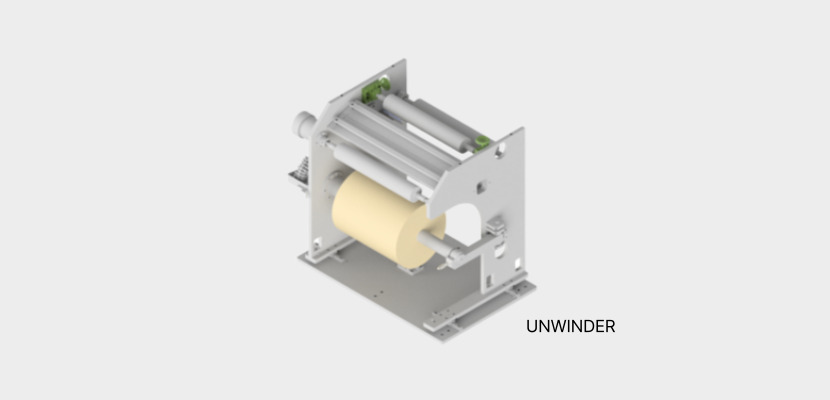

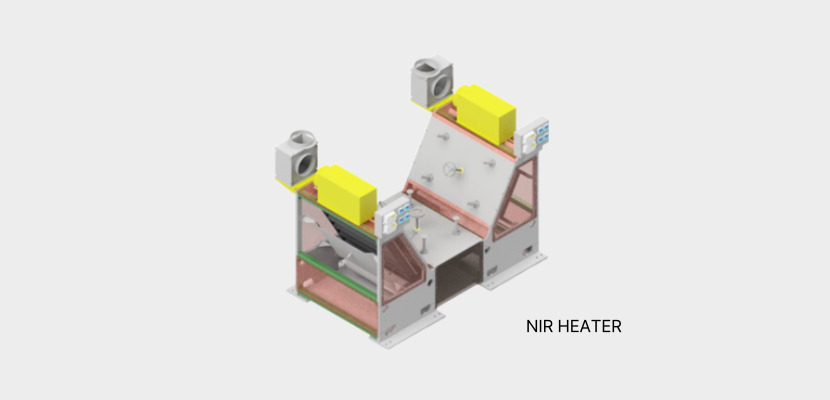

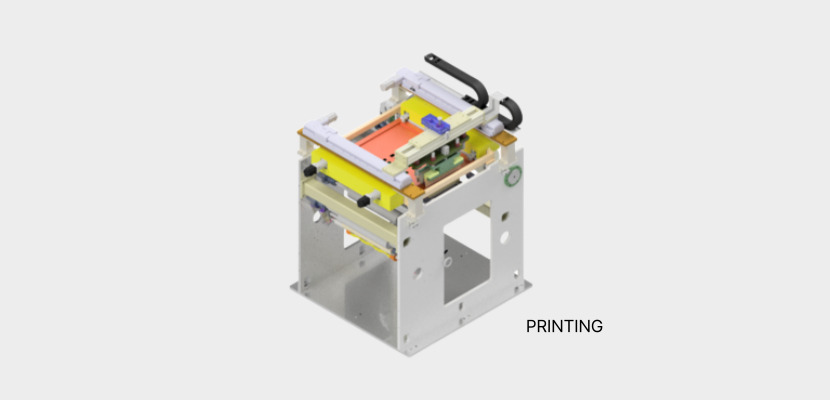

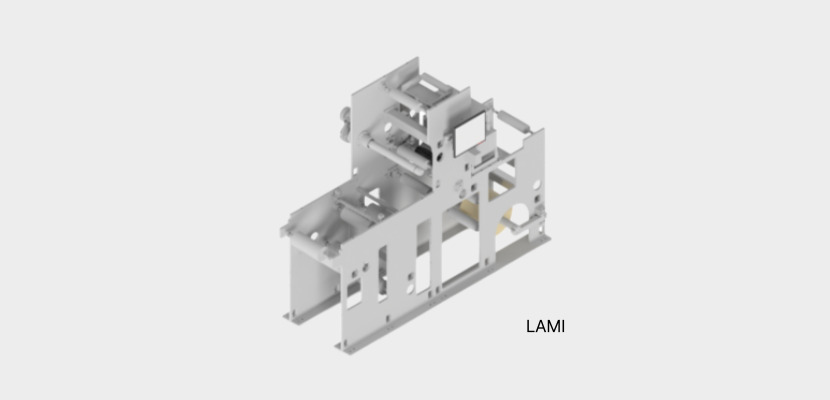

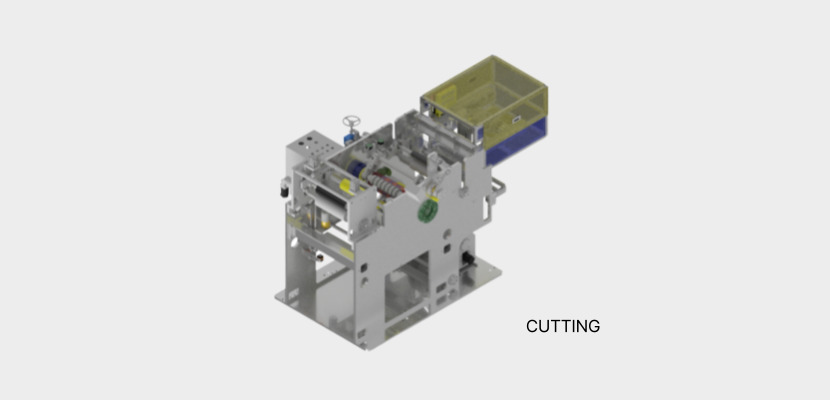

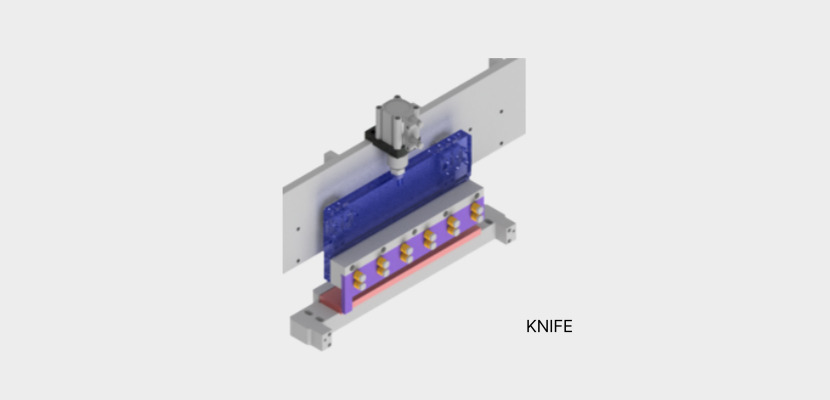

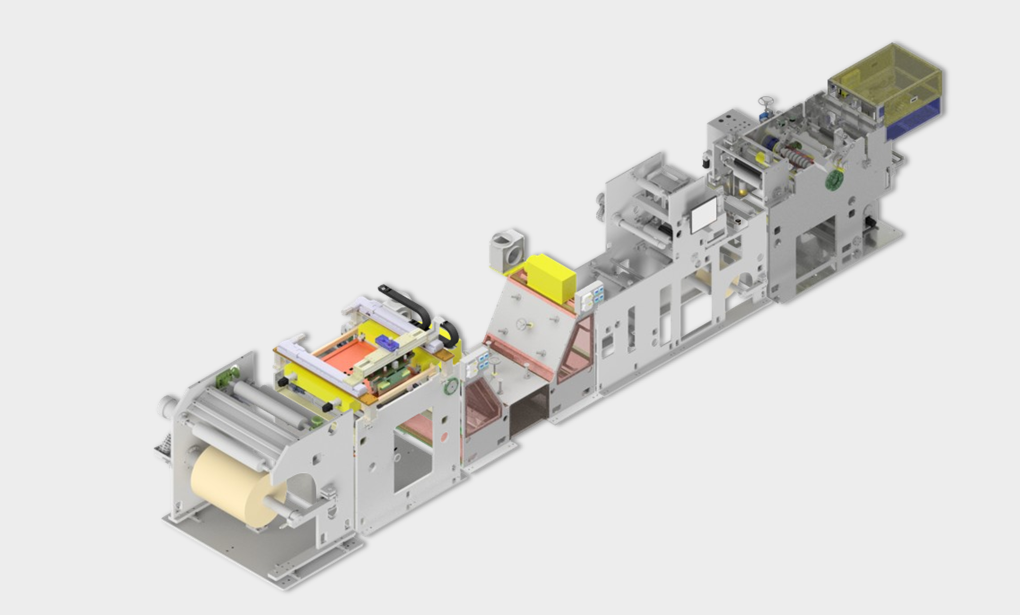

The ODF(Oral Dissolvable Film) Coater is a compact, fully automated solution that integrates multiple processes—from production to packaging—into a single system capable of printing various patterns on oral films. This full-auto system enhances production capacity and reduces manufacturing costs by combining precise printing technology, an automated production line, and a space-efficient drying solution for faster and more efficient ODF manufacturing.

Featuring high-precision screen printing technology, it supports a wide range of patterns and colors. Multi-layer printing allows multiple ingredients to be combined into a single film, enabling differentiated product development. By dispensing raw materials only immediately before printing, the system minimizes exposure to air, reducing degradation and contamination. Additionally, it uses a compact structure with NIR (Near Infrared) lamps, eliminating the need for a separate drying oven.

Specifications

| 구분 | 사양 |

|---|---|

| Coating Method |

Special Printing

|

| Web Width |

Max. 550m/m

|

| Web Thickness |

90μm ~ 150μm

|

| Guide Roll Width |

600mm

|

| Unwinding Diameter |

Max. Ø400mm

|

| Rewinding Diameter |

Max. Ø400mm

|

| Kind of Web |

PET, AL & PE

|

| Kind of Coating Chemical |

FoodㆍHealth Supplement Ingredients

|

| Solid Content |

20% ~ 50%

|

| Kind of Solvent |

Water based

|

| Coating Thickness (Wet Base) |

150 ~ 300µm

|

| Machine Design Speed |

Max. 4m/min

|

| Machine Operating Speed |

1 ~ 2m/min

|

| Utilities |

220V, 60Hz, 3 Phase, Max. 7Kg/cm²

|